Din offertförfrågan

Du har ännu inga varor valda för din offertförfrågan.

Andra populära produkter just nu

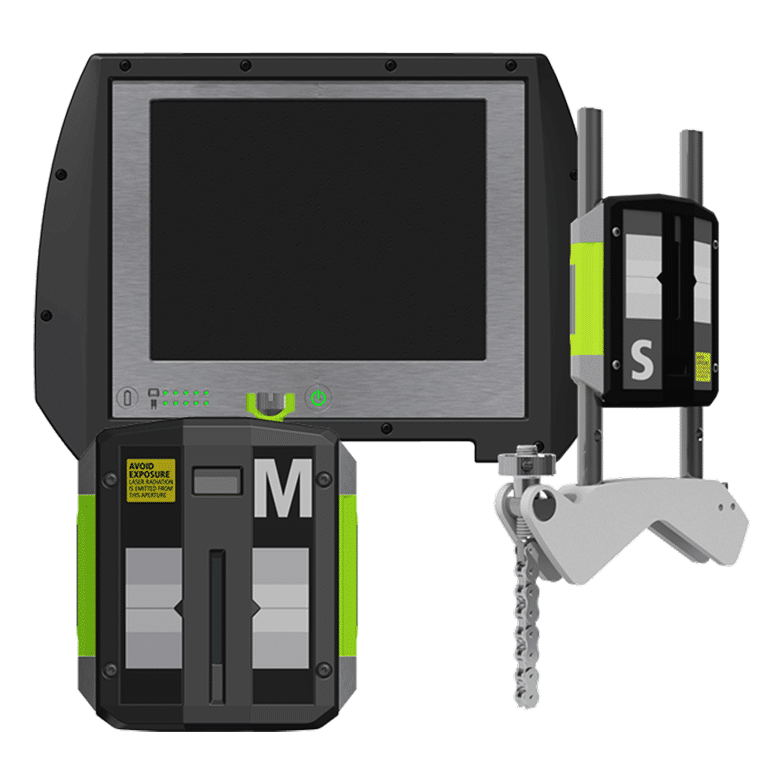

A revolution in shaft alignment as well as usability with the new NXA Pro – a shaft alignment system based on digital laser!

NXA Pro seeks to provide the user with quick and easy operation, as well as access to advanced functions and capabilities, such as OmniView™ and VertiZontal Moves™, and probably the best battery and charging features on the market.

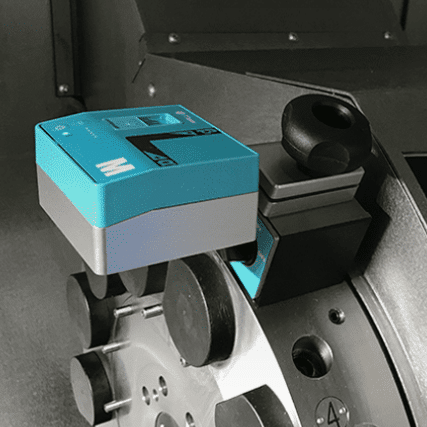

Meax® Level is a unique 2-axis high precision inclination sensor with a large measuring range (± 100 mm/m) with the same accuracy (± 5 µm/m).

The MEAX Level Single uses one 2 axes-sensor for different measurement tasks when checking the geometry status of machine tools. It uses the readings from the 2-axes level sensor and connects to any mobile device which displays the measuring results in the Meax Level App.

With Meax Level Single it is possible to measure an object’s inclination towards gravity (leveling) or to measure an object’s relative angular deviation (roll/pitch) during machine axes movement. The sensor can also be used to monitor any angular movements over time.

A unique feature of Meax Level is that combines a wide measurement range (±100 mm/m) with high accuracy (± 0,005/m) which is constant in its entire measuring range. This feature allows the MEAX Level sensor to be mounted on the surface using a magnetic base, in tool holders using a 16mm shaft holder, or to be mounted on customized fixtures which further increases the flexibility of the Meax Level Single system.

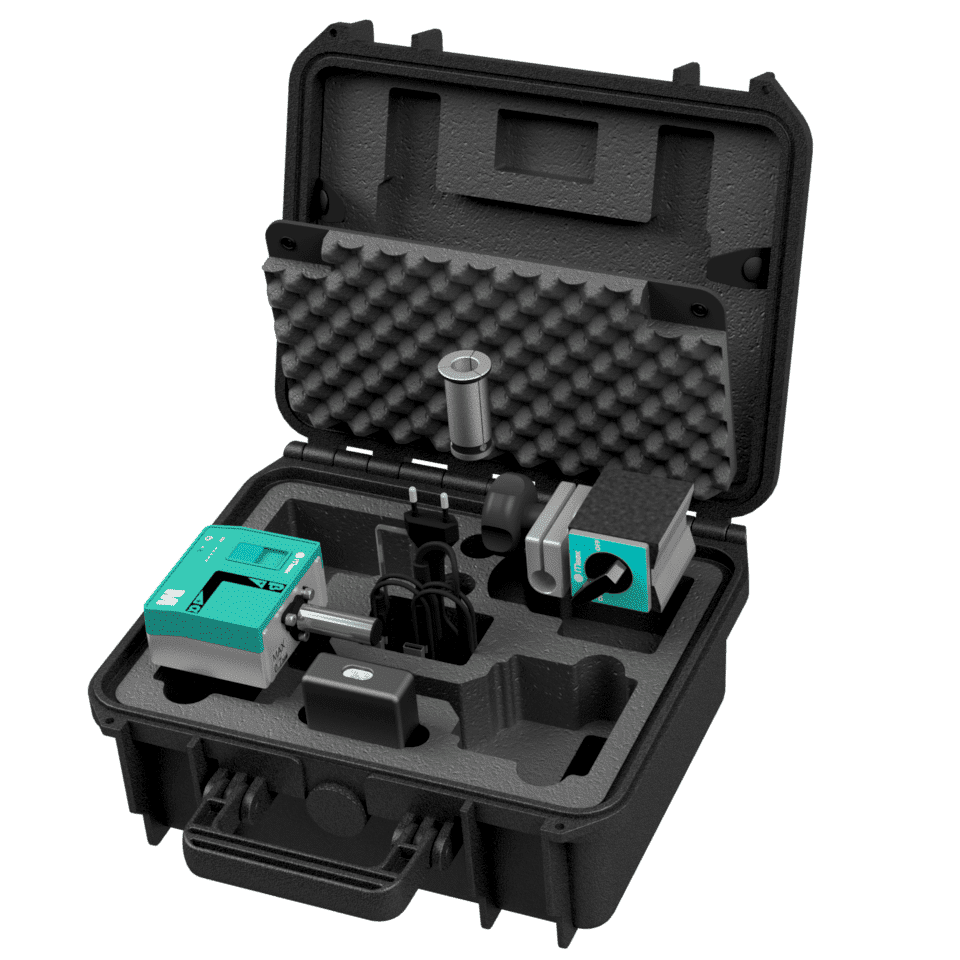

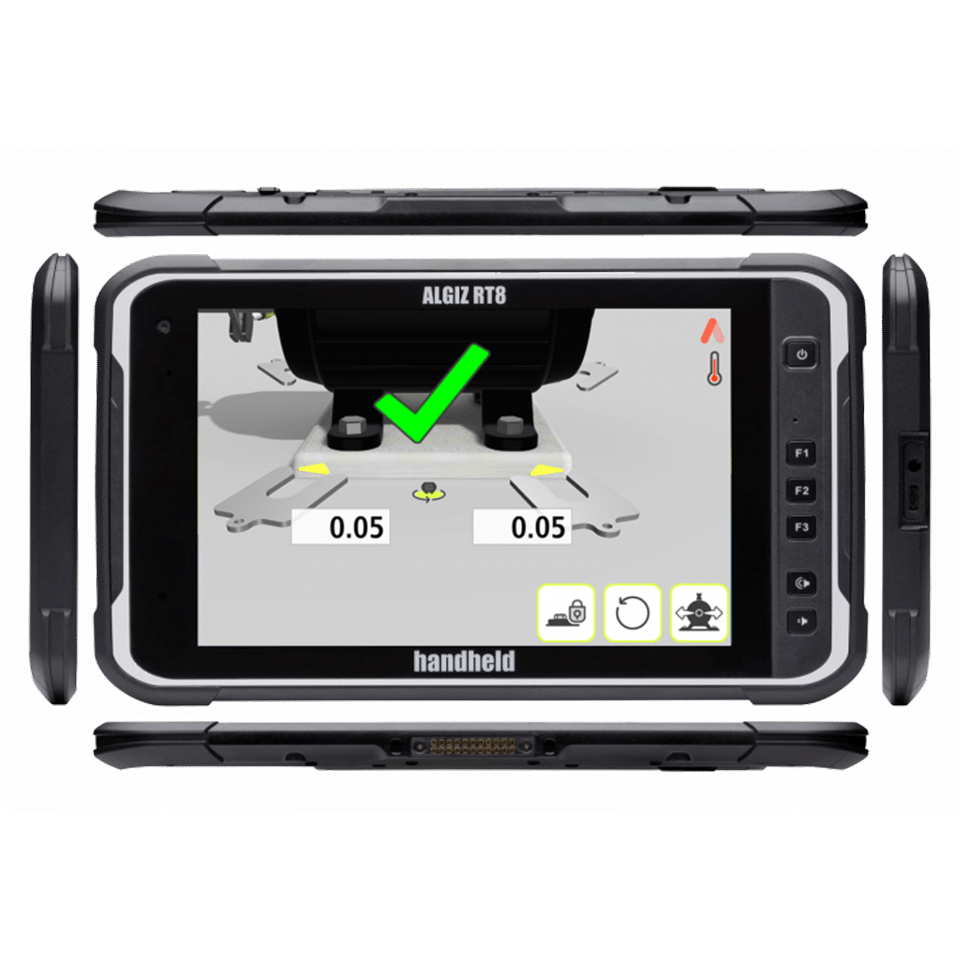

AT-100 is an app-based alignment tool that combines integrated apps, patented technology, and easy connectivity. The AT-100 is suitable for entry-level to expert shaft alignment work, the AT-100 shaft alignment tool provides high measurement flexibility. The intuitive tool works with the shaft alignment apps on a tablet or smartphone. It is simple to use and doesn’t require any special training.

The AT-100 shaft alignment solution is the result of almost 40 years of shaft alignment expertise and innovation, leveraging the latest technology to enhance your user experience.

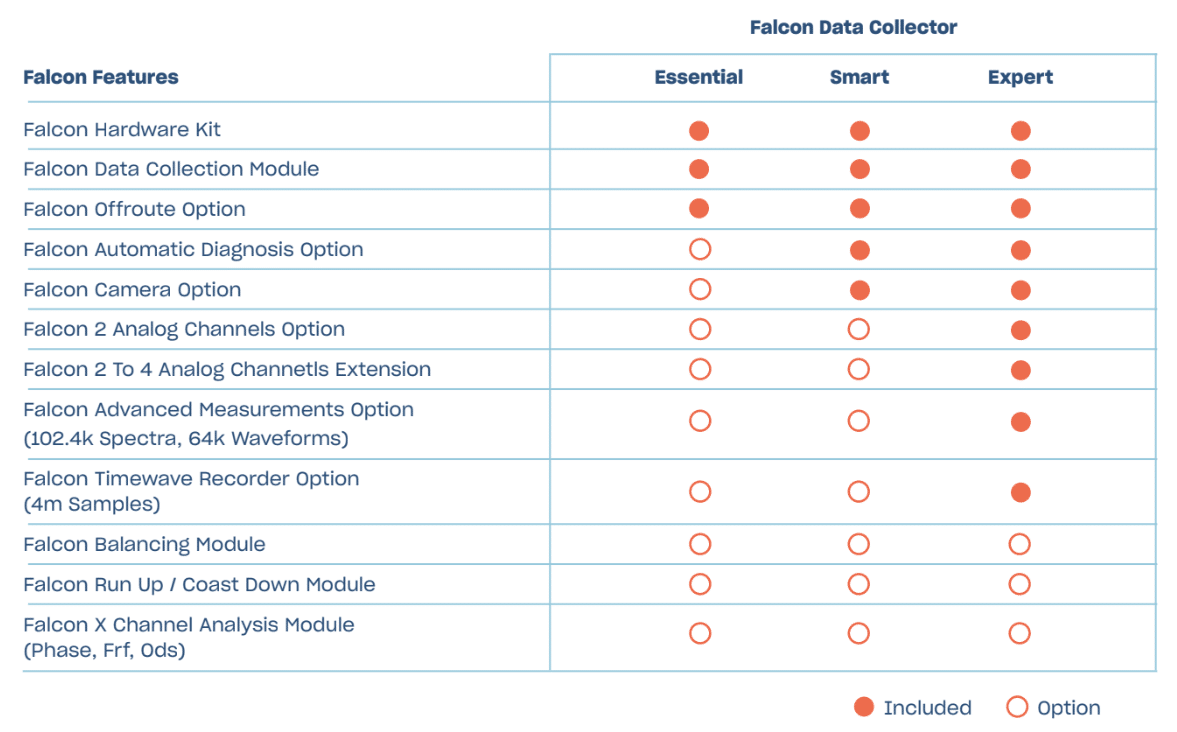

FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

With a wide range of optional features available, the FALCON can be configured to perform balancing, run up/ coast-down, frequency analysis and more.

– Wireless vibration analysis

– Graphical, touch screen interface

– Three-axis wireless sensor

– Ideal for route-based maintenance

– Fast vibration analysis: each bearing takes an average of 8 seconds to measure!

– Available in four configurations: Essential, Smart, Expert and Ultimate (full options)

– Built-in accessories: stroboscope, pyrometer, camera, QR code reader, and audio comment recorder.

– Acquisition of multi-channel time signals up to 80s at 51.2kHz (4 Mega samples)

FALCON is also available in EX versions.

FALCON is also available in EX versions.