MV-x: Black Edition

Realtime predictive maintenance powered by artificial intelligence (AI)

MV-x: Black Edition

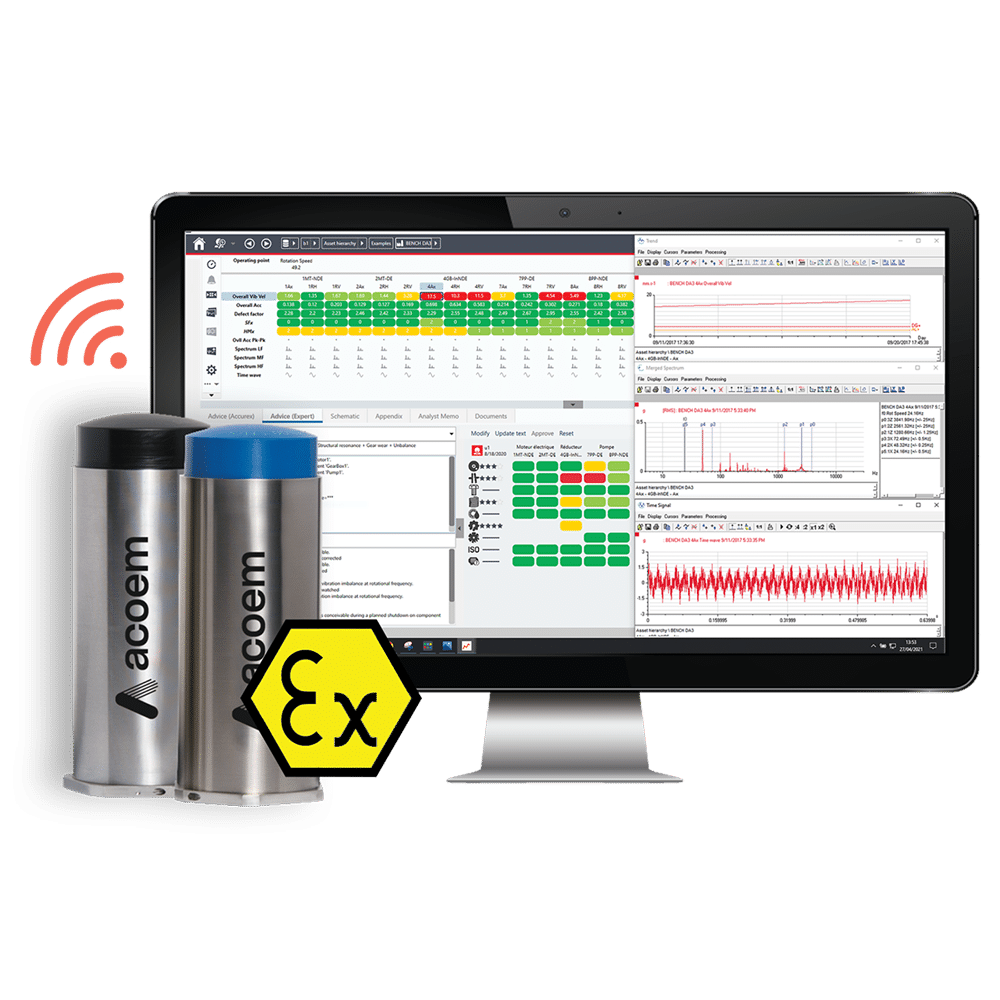

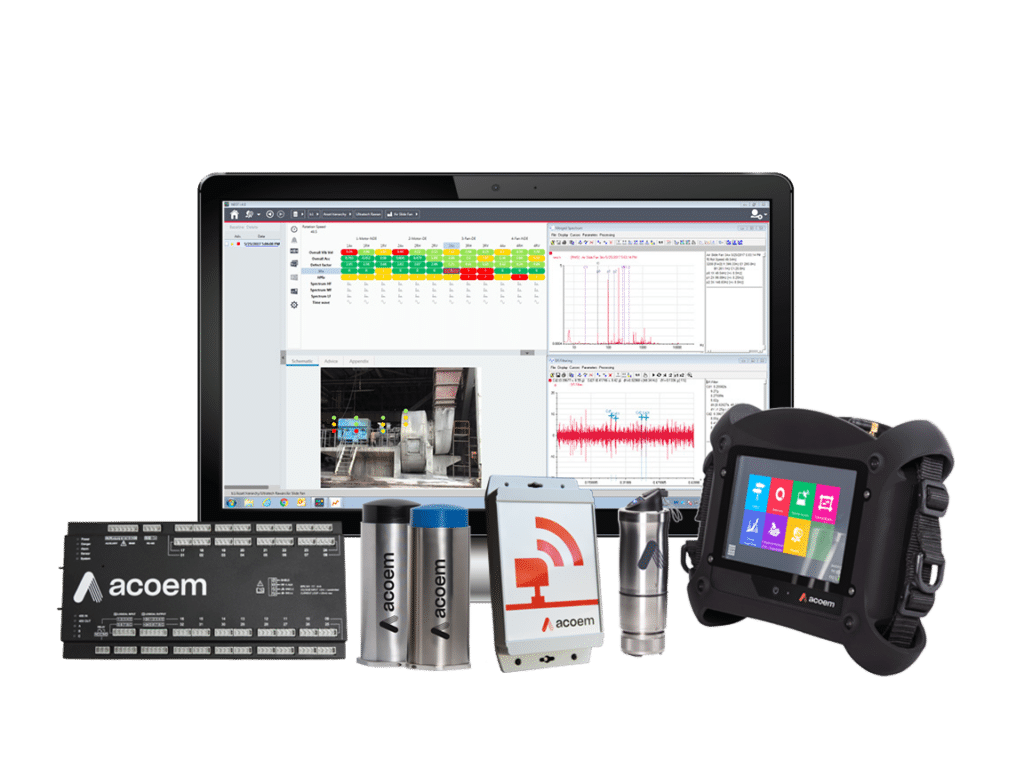

Acoem brings to you MV-x Black edition ,the next generation of AI-enabled vibrational analysis, with real-time edge computing, provides a pathbreaking predictive tool to pinpoint the source, direction, and intensity of the vibration. It represents a fundamental shift from reactive maintenance to predictive maintenance. More importantly, it provides vibration analysis and condition monitoring users, with a seamless industry 4.0 experience.

MV-x: Black Edition

Acoem brings to you MV-x Black edition ,the next generation of AI-enabled vibrational analysis, with real-time edge computing, provides a pathbreaking predictive tool to pinpoint the source, direction, and intensity of the vibration. It represents a fundamental shift from reactive maintenance to predictive maintenance. More importantly, it provides vibration analysis and condition monitoring users, with a seamless industry 4.0 experience.

Beskrivning

In the modern industrial environment, we face the challenge of effectively capturing accurate data at the right time, especially when it comes to machines operating under varying process conditions. This is crucial to enable reliable analysis and predict any potential faults. Acoem MV-x is the solution that makes all of this possible in today’s industrial processes:

- Up to 10 operating conditions can be defined using one or more process parameters.

- The data collection strategy, indicators, and alarm threshold values are automatically adapted for each operating condition.

- Stability parameters are configured to ensure that each measurement is carried out under optimal conditions.

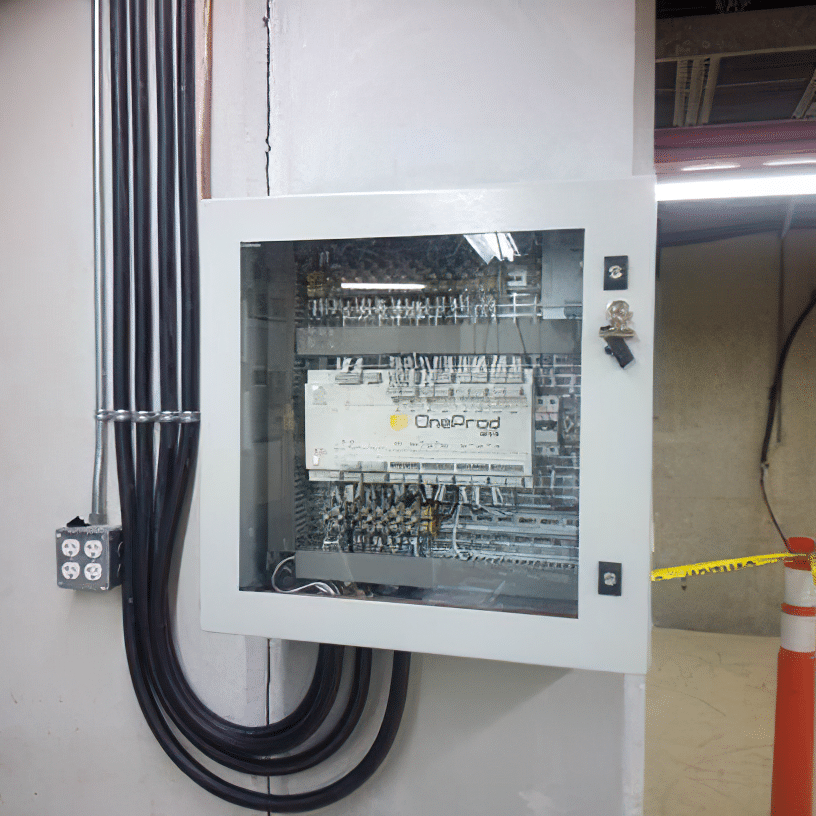

A centralized system

The data acquired by MVX is automatically stored in the NEST software platform. Analyzing and accessing the condition of production facilities is straightforward: reports are available with just a few clicks, and you can navigate from a world map to a detailed view of a machine. Regardless of the source of the measurements (a portable FALCON instrument, a wireless EAGLE sensor online, or an MVX cable monitoring system online), the data is accessible through the same interface from any connected computer.

Easy to deploy

MV-x communicates and transfers its results automatically and reliably to the NEST software via a secure Ethernet link. Operators can use the local cabled network, a Wi-Fi network, or over the Internet via a 4G link, for example.

Enhanced cyber security

At Acoem, we are aware of the importance of keeping your production or operational data secure. With the global rise in cyberattacks and infiltration of processing data, especially within sensitive industries, we have taken decisive action to change the way that your data is communicated through Nest i4.0. In addition to enforcing passwords and encrypted certificates, we have enhanced the way the MV-x system communicates with the software. Now encrypted communication remains an IoT initiative to keep your data more secure and protect it from possible access by external parties.

At Acoem, we are aware of the importance of keeping your production or operational data secure. With the global rise in cyberattacks and infiltration of processing data, especially within sensitive industries, we have taken decisive action to change the way that your data is communicated through Nest i4.0. In addition to enforcing passwords and encrypted certificates, we have enhanced the way the MV-x system communicates with the software. Now encrypted communication remains an IoT initiative to keep your data more secure and protect it from possible access by external parties.

Integrated into your environment

MV-x can be fully integrated into your environment. Process information is retrieved directly from the PLCs, eliminating any duplication of data. The advanced indicators defined can be transmitted to improve process management, and maintenance management is optimized thanks to an interface with the CMMS system.

Smart monitoring

Real-time monitoring of one or more machines. Storage of measurements required for analysis: the right information at the right time. Easy analysis of complex machines through management of operating conditions. Early detection of faults on slow shafts with Shock Finder.

Communication

Two-way communication with PLCs. Alerts by e-mail / logic outputs. Management of sub-optimal communication conditions (3G) for isolated machines.

Ytterligare information

| No. of channels | 6, 12, 16, 24, 32 |

|---|---|

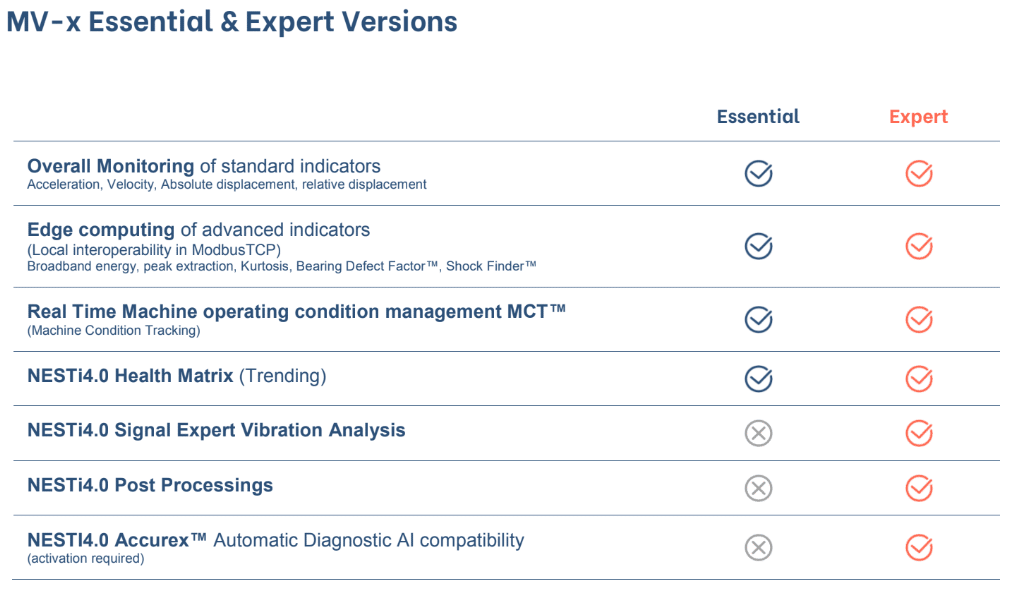

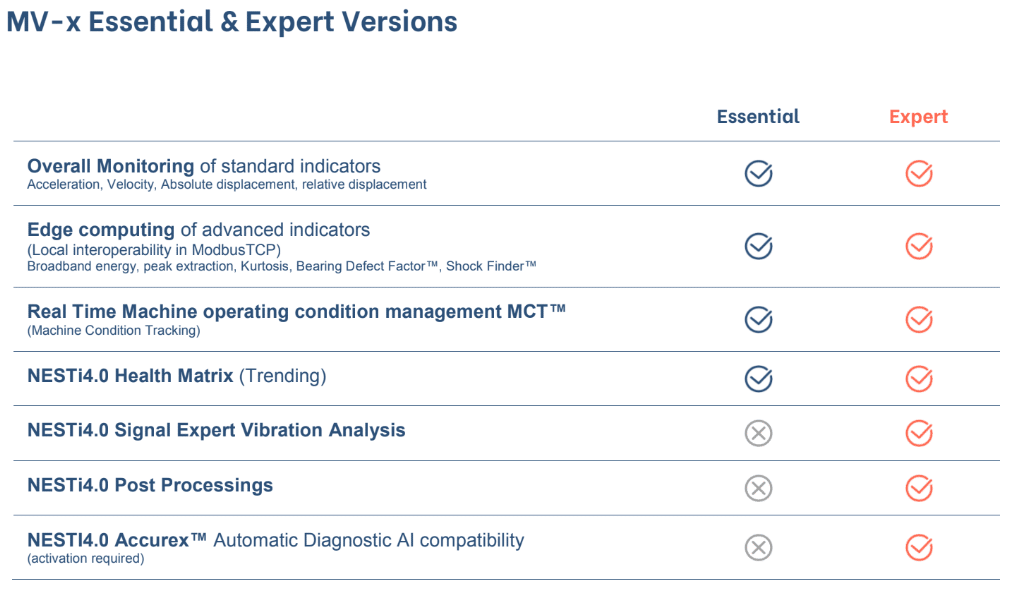

| Version | ESSENTIAL, EXPERT |