Eagle

Wireless diagnostic solution for critical assets

Eagle

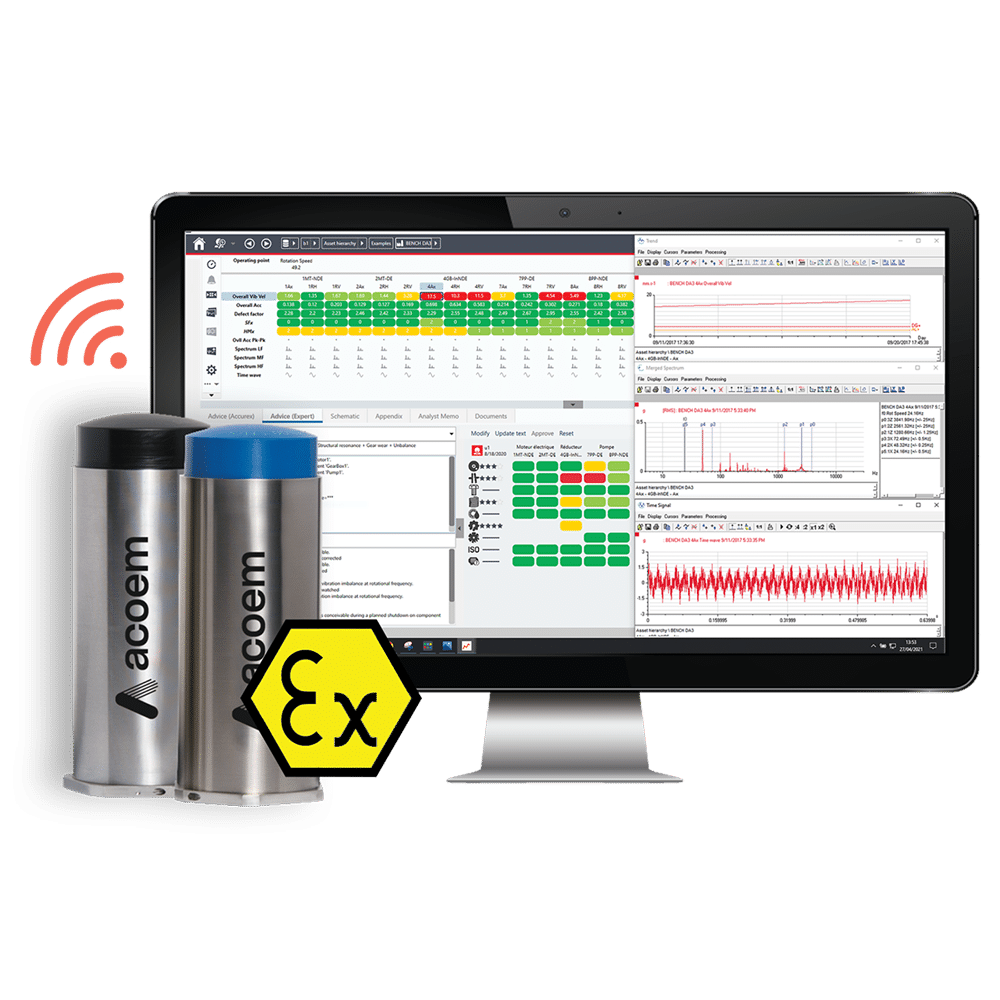

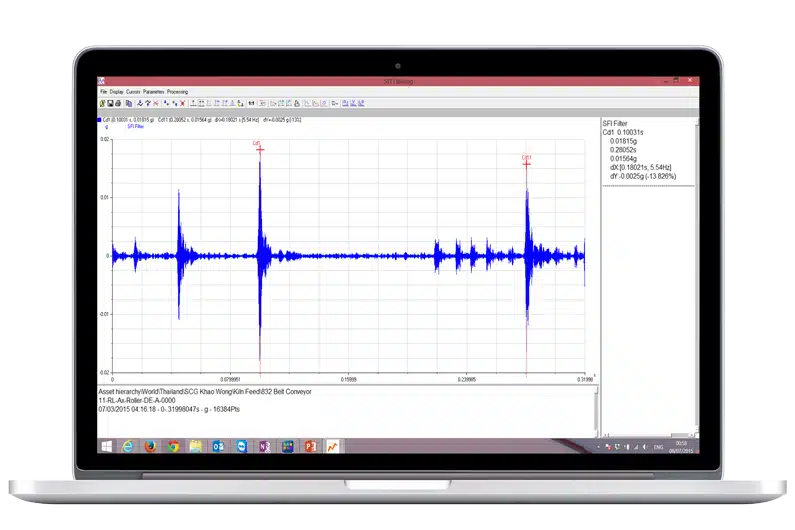

Acoem Eagle’s revolutionary wireless remote diagnostic solution is a true game-changer that safeguards crucial components of your rotating machinery. This cutting-edge technology efficiently detects faults, including bearing and gear defects, ensuring seamless operations and preventing costly setbacks for your business.

One of the key advantages of Acoem Eagle is its all-inclusive data provision. It measures automatically vibration in three directions as well as the bearing temperature, providing comprehensive data at your fingertips. With this information, there’s no need to send personnel on-site for additional measurements when an alarm is triggered. Acoem Eagle empowers you to conduct remote diagnostics effortlessly, right from where you are. Save time, resources, and minimize downtime with the power of Acoem Eagle’s wireless remote diagnostic solution.

Eagle

Acoem Eagle’s revolutionary wireless remote diagnostic solution is a true game-changer that safeguards crucial components of your rotating machinery. This cutting-edge technology efficiently detects faults, including bearing and gear defects, ensuring seamless operations and preventing costly setbacks for your business.

One of the key advantages of Acoem Eagle is its all-inclusive data provision. It measures automatically vibration in three directions as well as the bearing temperature, providing comprehensive data at your fingertips. With this information, there’s no need to send personnel on-site for additional measurements when an alarm is triggered. Acoem Eagle empowers you to conduct remote diagnostics effortlessly, right from where you are. Save time, resources, and minimize downtime with the power of Acoem Eagle’s wireless remote diagnostic solution.

Beskrivning

Monitor critical machinery

Eagle, with its advanced signal processing capabilities, calculates key indicators and performs envelope FFT locally. Trend analysis helps you make informed maintenance decisions and optimize machinery efficiency.

Unmatched diagnostic capabilities

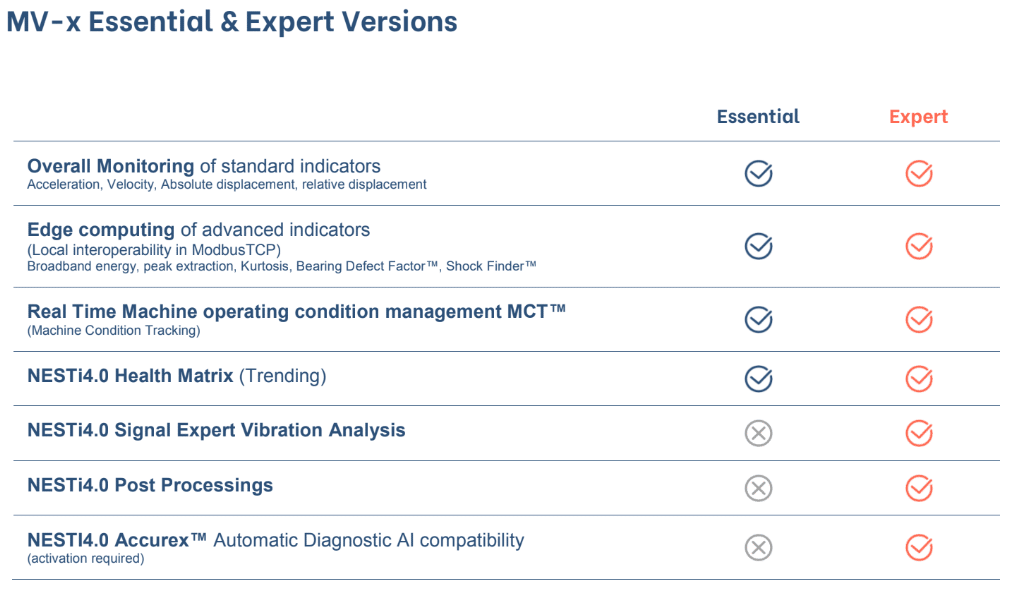

Eagle is a cutting-edge system offering vibration monitoring in one or three axes, along with temperature monitoring. It collects multiple FFTs for up to 20kHz analysis, provides real-time insights through edge computed indicators, and allows monitoring from as low as 100 RPM. Access advanced indicators and analysis tools through the NESTi4.0 software platform, empowering proactive maintenance and optimized machinery efficiency.

Harsh environment champion

The system is purposefully designed to meet industry requirements, with certifications for use in explosive area Zone 0 (Class I, Div I). Its stainless steel body ensures safety even in the harshest environments, while its IP67 rating guarantees resistance against corrosive conditions. The wireless and automatic operation removes the need for cables and manual inspections, making it ideal for challenging conditions.

Edge computing: Empowering real-time insights

Eagle enables data analysis to be conducted directly next to the machines, enhancing the reliability and repeatability of results. It calculates various vibratory levels, including velocity, acceleration, temperature, and peak-to-peak measurements, providing real-time insights and facilitating quick decision-making.

The smart sensor advantage

The sensor is embedded with Averaged Spectra for data analysis and accuracy. Moreover, Eagle is powered by Accurex’s automatic diagnostic AI, providing intelligent insights for smarter analysis.

Effortless maintenance: Prolonged sensor performance

Eagle ensures long-lasting operation with up to 5 years of reliable service, thanks to its user-replaceable batteries. The cost-effective standard batteries simplify maintenance and extend the sensor’s life, making it an efficient and economical choice.